- Company

- Industries

- Product areas

- Technology

- Jobs and Career

- Apprenticeship

- News

Miba's soft magnetic composites are used as actuators as well as in electrical machines. SMC materials stand out because of the compact design and optimized performance capabilities they offer.

Miba offers a broad range of soft magnetic materials. From DC applications to AC high frequency applications with up to 10.000 Hz.

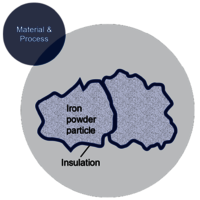

Altogether our soft magnetic composite components cover a frequency range from 50 Hz to 10.000 Hz. SMC components are compact, lightweight and have a high power density. They are made from iron powder particles and are coated with an electrically insulating layer. As a result, they have increased electrical resistance.

Continuous innovation is one of our core values. Our eMobility team knows how to design the electric motors of tomorrow. We don't just supply the soft magnetic composite components; we supply the complete system - that works perfectly.

Powder metallurgy is the optimal solution to produce superior performance in your axial flux and transverse flux motor designs. These are used in automotive, white goods, HVAC (heating, ventilation, air conditioning) and many other industrial applications.

We at Miba have developed an electric motor that is characterized by three key features:

MORE >

both size and weight of the components can be reduced

high power and torque density

net shaping production process with minimum waste and no need for rework

Through compaction and heat treatment, the particles can be formed into complex shapes, allowing a three-dimensional magnetic flux.

Get in touch now.

During the development of SMC components, we focus on four key factors:

Numerical simulation, customized design, system integration

Material competence center, prototyping, component manufacturing

Magnetic properties testing, electric properties testing,testing competence center

Manufacturers can use our expertise in powder metallurgy to develop robust electric motors. During the development process, we combine manufacturing technology with functionality.

Learn more about the advantages of soft magnetic composite components.

Soft magnetic materials possess high flux density and permeability. Using iron with various alloying elements makes customized magnetic performance possible. Thanks to the high degree of flexibility of the geometry, flux guidance can be customized so the space is used perfectly. In addition, net shape manufacturing enables large-scale production. That's how complex structures can be manufactured cost effectively.

Products that require the best soft magnetic properties include soft magnetic cores, inductors, actuators, and pole cores.

“In the relatively new area of integrating SMC components in electric motor or drive systems, we are a reliable and experienced partner for our customers. We are an internationally connected R&D team with focus on a smoothly running overall system.”

- Robert Hellein, Teamleader Materials Development -