- Company

- Industries

- Product areas

- Innovation

- Jobs and Career

- Apprenticeship

- News

Are you facing the challenge of choosing between a hydrodynamic bearing or a rolling bearing?

Find out which bearing technology best suits your needs in this blog article.

In hydrodynamic bearings, a lubricating film separates the shaft and the bearing from each other, minimizing friction and wear. The pressure build-up of the lubricating film is generated by the movement itself. This allows high loads and speeds to be reliably handled.

Find out more about hydrodynamic bearings on our axial and radial bearings product pages and our blog articles.

In contrast to hydrodynamic bearings, rolling bearings support the entire load with rolling elements. As the shaft rotates, balls or rollers move between an outer and an inner ring. This rolling motion is a combination of rolling and sliding. The service life is limited by material fatigue.

To select the right bearing for your application, it is important to understand its specific requirements. The following factors are key considerations for making a good decision:

| Hydrodynamic Bearings | Rolling Bearings | |

| Load Capacity | Hydrodynamic bearings have a larger contact area compared to roller bearings, which leads to an even load distribution and helps them to withstand higher loads. The lubricating film in hydrodynamic bearings ensures effective separation between the bearing and shaft. This makes them particularly suitable not only for high loads, but also for high speeds. | In rolling bearings, the load is distributed across fewer contact points. They are suitable for medium to high loads but can be overstrained and fail prematurely under extreme loads. |

| Noise Generation and Friction | As there is a lubricating film between the bearing and the shaft, there is no metallic contact, which means that these bearings operate almost silently. The lubricating film also minimises friction in hydrodynamic operation. Friction losses can be kept to a minimum by matching the lubricating oil (viscosity behaviour), speed range and bearing selection accordingly. | The direct, concentrated metallic contact in rolling bearings has lower noise-damping properties compared to hydrodynamic plain bearings. Due to the rolling contact, friction is usually low at operating conditions near standstill, approaching zero as speed decreases. However, as speed increases, additional effects such as cage friction can occur due to the more complex design, significantly increasing friction and potentially exceeding the sliding friction of bearings. |

| Space Requirements | If space is limited or there are strict weight requirements in your application, a hydrodynamic bearing is the perfect solution. With wall thicknesses of just a few millimeters, these hydrodynamic bearings require less space than roller bearings. This leads to weight savings that streamline the overall system, increase power density, and reduce material costs. | In most applications, the rolling bearing itself determines the available space for the entire system. Therefore, the selection of the appropriate bearing significantly influences the dimensions of the available space. |

| Vibration Behavior | In these hydrodynamic bearings, the lubricant film dampens vibrations, resulting in good vibration behavior. Thus, hydrodynamic bearings are ideal for applications with dynamic loading. | In contrast, rolling bearings transmit vibrations directly. These vibrations must be dampened. |

| Maintenance and Service Life | In hydrodynamic operation, there is no direct contact between the bearing surface and the shaft. By using a suitable lubricant and adhering to the application limits adapted to the system and the hydrodynamic bearing, the bearings operate wear-free. To ensure their optimum performance over the long term, it is only necessary to regularly check the lubricant for contamination and quality. Apart from this, hydrodynamic bearings are extremely low-maintenance. | Unlike hydrodynamic bearings, the service life of roller bearings can be calculated in advance under normal conditions. Material fatigue limits their duration of use. However, when considering total costs over the entire service life, using hydrodynamic bearings is usually more advantageous because they are more durable. |

| Rotational Speed Behaviour | Hydrodynamic bearings are ideal for very high speeds because they build up a stable lubricating film through hydrodynamic lubrication. This minimizes friction and prevents direct metal contact, thereby reducing wear. They are extremely efficient, especially in continuous operation and at high circumferential speeds. | Rolling bearings are well suited for low to medium speeds, where they operate efficiently due to their rolling friction. At very high speeds, friction and heat generation can become a problem due to the rolling elements and cages. Their limiting speeds are limited by their design. |

| Shock resistance | Hydrodynamic bearings are particularly robust against shock loads. The lubricating film dampens and the flat contact distributes forces evenly and prevents local overloads. They are therefore advantageous in environments with shock loads and frequent load changes. | Rolling bearings are more sensitive to shock loads, as the point-specific force transmission between rolling elements and raceways can lead to material fatigue. A low-shock environment is therefore crucial for reliable operation. |

| Sensitivity to dirt | Hydrodynamic bearings are significantly less sensitive to dirt particles, as the lubricating film and the corresponding embedding capacity of the bearing materials can often bridge minor contamination without causing damage. Their simple design without moving parts reduces the risk of jamming due to foreign objects. This makes them well suited for use in dusty or dirty environments. | Rolling bearings are more sensitive to dirt, as foreign particles between the rolling elements and raceways can lead to increased wear or material damage. Even the smallest contaminants can severely impair precision and service life. That is why they depend on good sealing and clean operating conditions. |

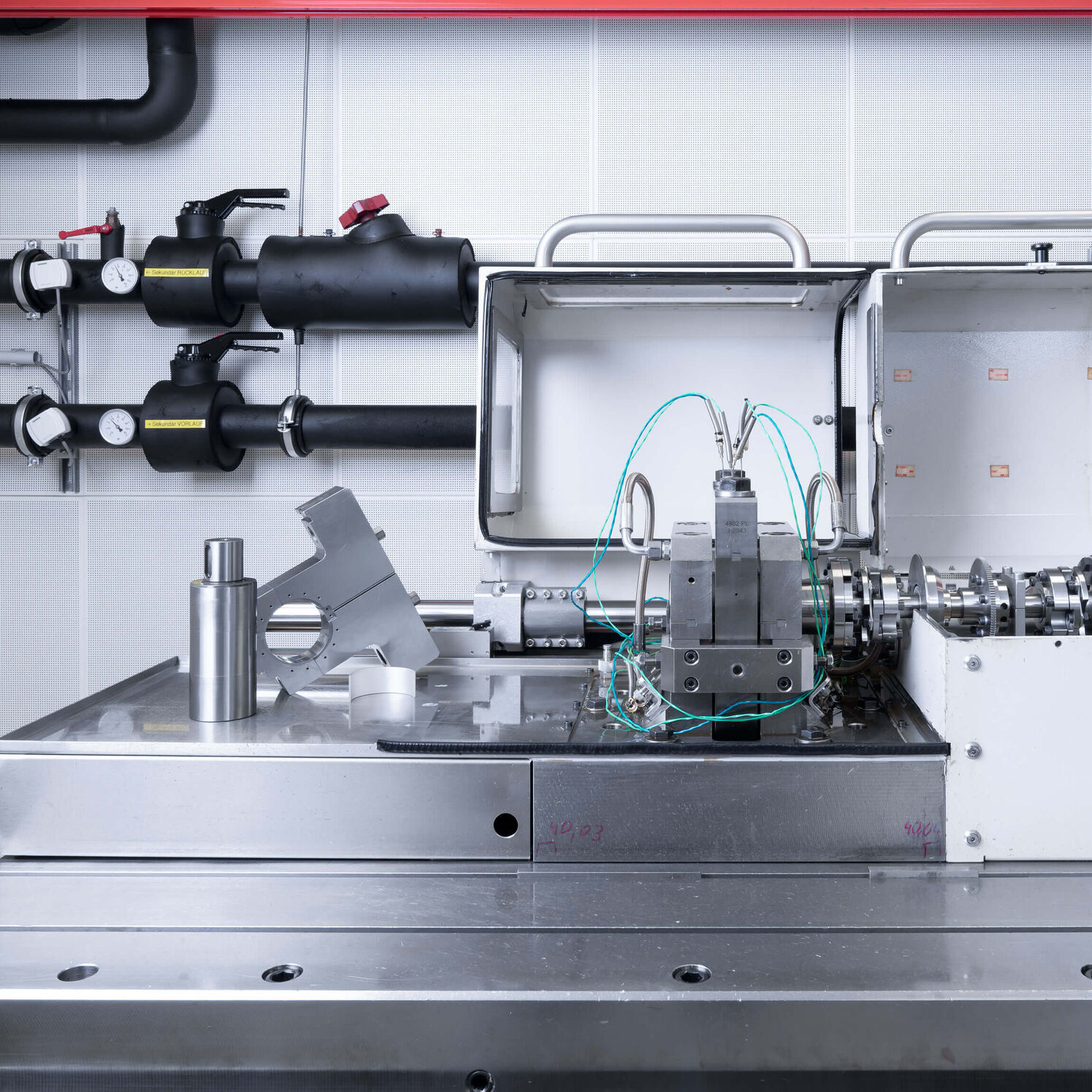

Replacing conventional rolling bearings with hydrodynamic bearings is not only technologically convincing in numerous applications, but also creates a real competitive advantage. These bearings save space and weight while handling higher loads. The lubricating film of the hydrodynamic bearings significantly reduces maintenance requirements, while vibration damping and smooth running also ensure increased reliability. Applications in pumps, compressors, and gearboxes already demonstrate the successful transition from rolling bearings to hydrodynamic bearings.

Switching to hydrodynamic bearings is that easy

Switching from rolling bearings to hydrodynamic bearings is easier than often assumed: Miba develops hydrodynamic bearing solutions that can usually be integrated very easily into existing environments - without costly design changes. In many cases, lubrication systems can also continue to be used. This significantly reduces the amount of adaptation required and makes the switch quick and economical.

Details can also be found in the technical article in "Konstruktionspraxis".

In addition, we support our customers from the very beginning through all project phases—from the initial idea to after-sales service.

Our blog offers in-depth insights, practical tips and the latest technological innovations. Stay up to date with expert knowledge, exciting developments and valuable industry insights!

Not sure whether hydrodynamic bearings are suitable for your system? Find out in just a few clicks with our bearing calculator.