- Company

- Industries

- Product areas

- Innovation

- Jobs and Career

- Apprenticeship

- News

Miba offers a comprehensive service portfolio for industrial hydrodynamic bearings – from development and design to production, maintenance, repair and retrofitting. In addition, our “Optimization & Upgrades” service division supports customers in further developing existing bearing systems and sustainably increasing their performance. Our product range also includes training courses on the basics and practical application for optimal bearing design.

When operating conditions change or requirements increase, it is crucial to start optimizing the bearing system at an early stage. Otherwise, potential weaknesses may become apparent in the following areas, among others:

· Excessive bearing temperatures lead to a shorter service life

· Bearing failures cause unplanned downtime and consequential damage

· Seals or oil systems are not optimally matched to the system

Such challenges have a direct impact on productivity, operating costs, and plant availability. We are at your side as experts right from the inquiry stage, because many of these problems can be solved sustainably through targeted technical optimizations.

Let our experts analyze your storage solution.

Not every challenge requires a new development. Often, targeted interventions can get more out of bearing systems – without the need for a complete redesign. Miba offers a comprehensive optimization and upgrade program tailored to your specific systems.

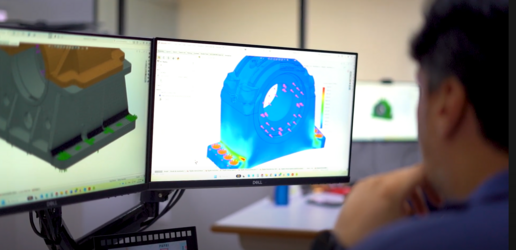

Our experts conduct a structured analysis of your existing bearing design. This identifies weak points, reveals potential, and derives concrete opportunities for improvement.

Whether it's the bearing geometry, interaction with the lubrication system, or the installation situation – we take a holistic view of the system.

If problems arise, we provide fast and targeted support. Our Bearing Judgment Team analyzes bearing failures on site or using the data provided. It also develops proposed solutions to prevent future damage.

We also provide advice and operational support for the assembly and disassembly of complex bearing units.

Technical knowledge is a key factor for success – that's why we offer customized training formats:

Training courses can be conducted online, in-house, or on-site. We are happy to tailor training courses to your specific challenges.

Technical optimizations must deliver measurable benefits in use. Miba does not develop standard solutions, but analyzes each application individually and offers targeted measures that have proven themselves in practice.

Typical optimization examples from customer projects:

“In many cases, significant performance improvements can be achieved with minimal intervention – provided that the entire system is understood."

Sascha Macke

Service expert at Miba

Targeted adjustments can deliver significant performance improvements – often without the need for costly modifications. Our optimizations result in:

Improved lubrication, optimized seals, and lighter materials reduce downtime and operating costs. At the same time, these measures help to fulfill compliance with legal environmental requirements.

Many customers achieve a clear competitive advantage as a result – with stable processes and manageable investment.

With over 90 years of experience in bearing technology, Miba is your reliable partner for demanding applications. We combine in-depth system knowledge with innovative manufacturing and simulation methods.

Our global service network, tested solutions, and cross-industry expertise enable measurable results and sustainable competitive advantages for you.

Optimization is usually worthwhile when operating conditions have changed, recurring problems arise, or new requirements (e.g., environmental regulations) must be met—often with significant effects even with minor adjustments.

We also optimize products from other manufacturers. What matters most to us is that the solution fits your application—regardless of the manufacturer.

After initial data collection (e.g., operating conditions, damage patterns, photos, or bearing assessment), we analyze the situation, develop recommendations for action, and support implementation—on site if desired.

Yes, that is actually ideal. Many measures can be implemented efficiently during planned maintenance windows, e.g., conversions, material changes, or design adjustments.

Often immediately: lower temperatures, less vibration, and optimized lubricant consumption are evident right after startup.

We evaluate each measure individually — both technically and economically. The investments are often significantly lower than those for a new development or frequent replacement purchases.

Yes, our engineers have application experience in various industries and tailor solutions precisely to the specific requirements of each industry.

Yes, Miba offers basic and application-specific training courses. Contact us for specific training offers.

We would be happy to advise you. Fill out the contact form and our team will get back to you shortly to discuss your request personally.