- Company

- Industries

- Product areas

- Innovation

- Jobs and Career

- Apprenticeship

- News

Miba axial flow motors are characterised by compactness, a high degree of integration and customer-friendly assembly. They are mainly used in auxiliary drives, for example in electric hydraulic and pump units.

- High torque density thanks to SMC

- Integrated into product solutions

- Efficient use of materials and resources

- Pre-assembled

- EOL approved

- Easy assembly process at customer site

- Customized design

- Seamlessly installed

- Price advantage due to reduced number of engine components

Let's talk about Axial Flux Motors and its advantages.

Arrange a consultation appointment now.

Axial flux motors are used when installation space is at a minimum and thus a disc-shaped design is helpful. This makes them suitable for a range of high-performance applications in the drive train where space is limited, such as

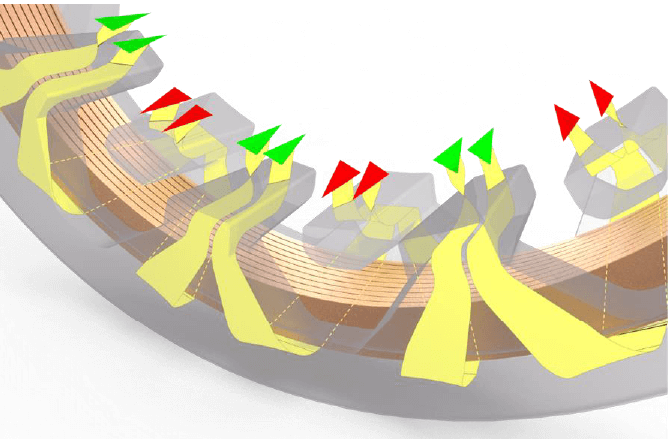

Miba axial flux motors with soft magnetic composite (SMC) material enable efficient guidance of magnetic fields in all three dimensions (3D flux). A unique combination of SMC with electrical laminations provides the ideal balance between high material saturation and maximum flux utilisation for efficient axial flux motors.

Learn the key benefits of soft magnetic composite components for both engine design and production processes on our SMC page.

We would be happy to tell you more about it.

Contact us now.

The difference is already apparent in the installation dimensions. The axial flux motor is built extremely compactly, but at the same time the power and torque remain high.

In this motor, the stator is installed next to the rotor disc, not outside as in RF motors. The direction of the electromagnetic flux is essential. In an axial flux motor, it flows parallel to the axis of rotation of the motor. In the radial flux motor, on the other hand, it flows perpendicular to the axis of rotation along an outward radius.

Thanks to many years of experience in the development of radial and axial flux motors, we can offer individual solutions with optimal cost efficiency and unique product designs for every customer requirement.

SMC components are essential components of an axial engine. For production, we rely on Miba Sinter Group's extensive know-how in powder metallurgy. The ability to shape this soft magnetic composite material into almost any form without considerable effort makes powder metal an essential component in the production of SMC components.

We support you in the development of your axial flux motor right from the start. Our team of experts accompanies you through the entire product development process from the initial concept, through simulation, prototype construction to series production.

With 30 production sites worldwide and a network of experts in Europe, America and Asia, we support you regardless of your location. You benefit from the comprehensive know-how of our R&D teams worldwide.

"The installation space requirements of axial flux motors make very short electric motors possible, which at the same time are characterised by their high material efficiency. Combined with a well thought-out design concept, this results in commercially advantageous solutions for many areas of electrical drive technology."

- Dietmar Andessner, Team Lead Product Development eMotors -