- Company

- Industries

- Product areas

- Innovation

- Jobs and Career

- Apprenticeship

- News

Friction materials of the Miba Fictrion Group are a key performance element in clutches and brakes in the international automotive and machine industries. By developing new friction materials and continuously improving existing friction materials, the Miba Friction Group is making a significant contribution to overall efficiency improvements to clutch and brake systems.

Whether construction equipment or mining vehicles, high-speed trains, aircraft, trucks or passenger vehicles – manufacturers and suppliers from a variety of industries trust the friction material solutions of the Miba Friction Group. As a development partner and supplier, we accompany our partners all over the world. Four global production sites allow us to respond quickly and flexibly to our customers’ needs and requirements.

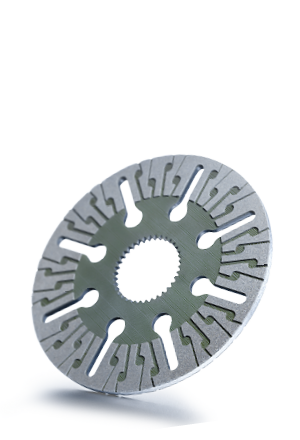

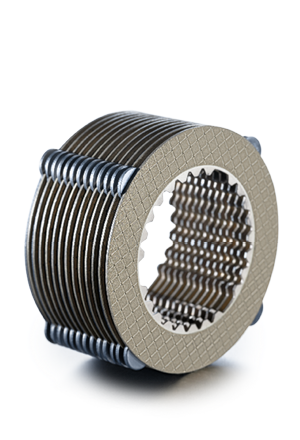

The Miba Friction Group’s friction materials are used as wet- and dry-running components in the clutches and brakes of vehicles, machinery, aircraft and wind power plants as well as for industrial applications such as in the field of freight handling. In addition to in-house production of steel discs, Miba develops and produces fiber composite, sintered, ceramic, carbon and molybdenum friction materials. Our aim is to guarantee greater performance and operational safety through optimized friction coefficients and the best wear properties for ever smaller and lighter components.

At the starting line: A new generation of clutch systems. The clutch friction lining is mainly responsible for transferring engine torque, wear and tear on the pressure plate and shifting comfort. Frequent shifting in construction vehicles and other specialty vehicles exposes the friction material to a high level of stress. We are taking on this challenge and offering the right solution with Miba PCC.

A state-of-the-art research and development center enables us to continually improve Miba friction materials and develop new ones. Wet- and dry-running clutch and brake systems can be tested under various conditions according to individual customer specifications on over 20 component and system test benches. A wide variety of materials ranging from fiber composites to sintered materials through molybdenum and carbon are developed, tested and analyzed in our laboratory. Miba therefore has one of the world’s most comprehensive material portfolios for friction materials for clutches and brakes.

Our Technology Leadership is based on continuous fundamental research in cooperation with international research centers and universities. We are familiar with the technological trends and offer our customers efficient friction material solutions.

Production and sales sites on three continents allow the Miba Friction Group to respond quickly and flexibly to the needs of our customers around the world, providing them with high-quality friction material solutions.