- Company

- Industries

- Product areas

- Innovation

- Jobs and Career

- Apprenticeship

- News

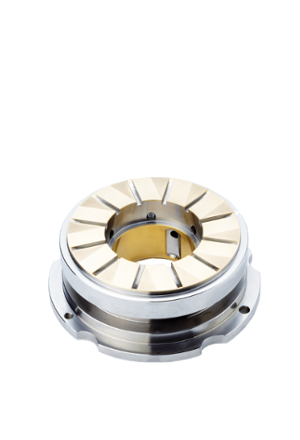

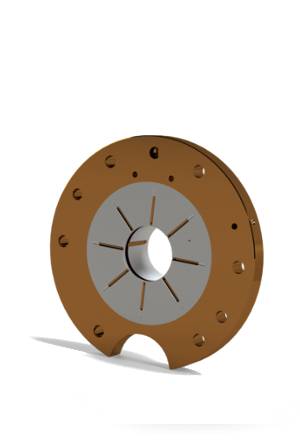

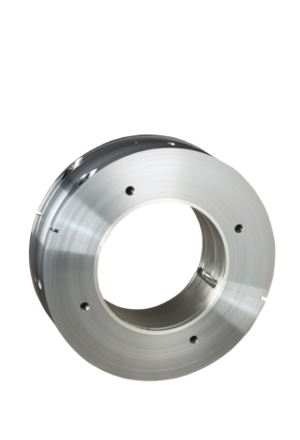

Using Miba Fixed Geometry Bearings (or Sleeve Bearings) is an economical way to achieve good rotor dynamic performance. Miba bearings are characterized by their precise bore tolerances and are highly customizable so you can dial in the stiffness and damping coefficients to optimize your machine’s performance. Some of the many bore configurations possible are: cylindrical, offset half, lemon bore, 3-lobe, 4-lobe, or directed lobe and can be provided with fixed flat land, taper land, compound taper land, or tilting pad thrust options.

Depending on the application, the journal bearing has a cylindrical bore, offset halves, lemon bore, 3-lobe or 4-lobe bore. Each design has different benefits and characteristics. Our engineers will help you to find the best solution.

Benefits of Fixed Geometry Bearings

Benefits include no metal to metal contact between the shaft and bearing while the machine is operating as well as dampened, low-oscillation, noise-free, and wear-free shaft operation. If the oil supply is operating properly, in theory, unlimited bearing service life is given.

| Bore | Peripheral speed* | Surface pressure* | ||||

| Cylindrical | 0 - 35 m/s (0 - 115 ft/s) | 0,2 - 5 MPa (30-700 psi) | ||||

| Lemon Bore | 25 - 80 m/s (80 - 260 ft/s) | 0,2 - 4 MPa (30 - 600 psi) | ||||

| 3 - Lobe | 30 - 100 m/s (100 - 330 ft/s) | 0,1 - 3,5 MPa (20 - 500 psi) | ||||

| Offset Halves | 20 - 100 m/s (70 - 330 ft/s) | 0,2 - 4 MPa (30 - 600 psi) | ||||

| 4 - Lobe | 30 - 100 m/s (100 - 330 ft/s) | 0,1 - 2,5 MPa (20 - 350 psi) |

*empirical values. Final design depends on application. Contact Miba for consultation.