- Company

- Industries

- Product areas

- Innovation

- Jobs and Career

- Apprenticeship

- News

Compact precharge resistors from Miba for battery connection boxes in electric cars ensure fast and safe precharging of the DC link capacitor:

• Up to 1,000 V without additional cooling

• High pulse energy with very short charging time

• Extremely durable with up to 300,000 precharge cycles

Without high-quality precharging, there is a risk of extremely high inrush current peaks, which can damage capacitors, relays, and fuses. Professional precharging is therefore essential.

High-quality Miba PREcharge resistors offer the following advantages over other products and solutions:

• Safe current limitation and thus safe precharging within ~1 second

• Limited current rise

• Protection of power electronics

• No cooling necessary

• AEC-Q200 Ready

• Long service life ~300,000 pulses

• Flexible designs and connection options

We are happy to advise you! Arrange a non-binding consultation appointment now.

The following precharge resistors are designed for battery connection boxes and DC link precharge circuits and meet the requirements of modern high-voltage systems in the electric vehicle sector.

You can also view the individual precharge resistors in our catalog.

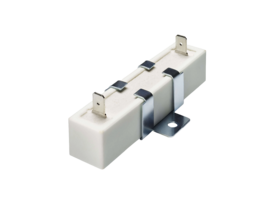

Compact, narrow precharge resistor for space-optimized designs:

• Operating voltage up to 1,000 V

• Ohm range 10 Ω – 300 Ω

• Continuous power 15 W at 85 °C

• FAST-ON connection, optional clip available

• High short-term overload capacity for individual pulse events without cooling

→ Suitable for battery connection boxes with very limited installation space

![[Translate to English:] Vorladewiderstand RST 100](/fileadmin/_processed_/1/4/csm_Precharge_Resistor_RST_100_fe20d233d7.png)

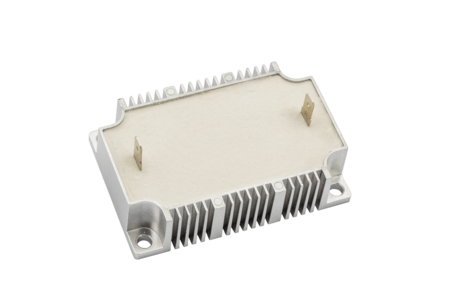

Precharge resistor with aluminum housing for improved heat dissipation:

→ Suitable for precharging processes with recurring pulse-like loads

High-performance precharge resistor for maximum pulse load:

Operating voltage 1,000 V

Ohm range 10 Ω – 300 Ω

Continuous power 80 W at 85 °C

FAST-ON or cable connection possible

Very high pulse energy thanks to aluminum housing and optimized thermal resistance

→ Suitable for high-performance DC link systems and repeated fast charging

Precharge resistor in fuse format for easy integration:

→ Suitable for modular battery and inverter systems with fuse layout

Contact us now. We are happy to advice you!

Prelading resistors or precharge resistors are used in a wide variety of ways in high-voltage systems. For this reason, the focus is not on standard components, but on precise technical adaptation to the respective system architecture.

This is how the customer-specific development process for our prelading resistors works:

1. Clarification of requirements

2. Electrical and mechanical design

3. Thermal optimization

4. Validation in our in-house laboratory

5. Series production according to IATF 16949

“Our products can be customized to meet customer requirements. This includes electrical, mechanical, and thermal design. As a result, each HV system receives a precisely matched precharge resistor with high pulse energy and long-term reliability.”

- Norbert Scharinger, Sales Manager E-Mobility -

Precharge resistors are safety-relevant components. Therefore, the focus is on reproducible series production and stable performance throughout the entire vehicle life cycle.

Testing and inspection processes

Every component is tested before delivery. This includes, among other things:

All precharge resistors are 100% end-of-line tested to ensure consistent performance.

Precharge resistors are manufactured in several international production plants, including:

This enables short delivery routes and technical support for OEMs and Tier 1s in Europe, North America, and Asia.

A precharge resistor limits the inrush current when the high-voltage system is switched on, so that the DC link capacitor is charged to battery voltage in a controlled manner rather than abruptly. This reduces the load on capacitors, fuses, and relays and increases the reliability of the high-voltage system.

In a correctly designed system, precharging takes less than a second without thermal overload.

It is not only the ohm value and voltage resistance that are decisive. For an optimal design, the following must be taken into account:

• Capacity of the DC link capacitor

• Target precharge time

• Pulse energy and repetition rate

• Temperature control

• Installation space and connection technology

We provide support here at an early stage of development upon request.

Yes, individual pulses up to 1,000 volts can be processed without additional cooling if the precharge resistor is correctly designed.

For high pulse frequencies or continuous loads, thermal optimization via aluminum housings is recommended.

Yes, the shape, housing, contact surfaces, and connections can be customized to customer specifications, e.g., FAST-ON, cables, or other connections as requested by the customer.

• Automated production in accordance with IATF 16949

• AEC-Q200-ready, tested for temperature change, EMC, moisture resistance, and solderability

In addition, 100% end-of-line testing is part of the manufacturing process.

The precharge resistors are designed for an exceptionally long service life — up to 300,000 PREcharge pulses in high-voltage applications.

Typically within a few weeks, depending on the connection variant, geometry, and validation requirements.

Yes, if it makes sense in terms of the system architecture, both active precharge resistors and passive or active discharge functions can be integrated into a single module.

Yes, precharge resistors are manufactured at several locations (Austria, China). This ensures regional stability in supply chains and enables project-dependent redundancies.