- Company

- Industries

- Product areas

- Technology

- Jobs and Career

- Apprenticeship

- News

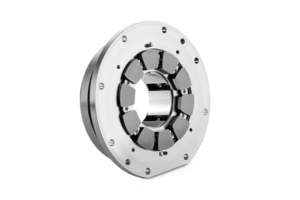

Bearings are key components in many machines and systems - understanding them is crucial for efficiency, service life and operational safety. In our practical bearing training courses, you will gain in-depth knowledge of the design, calculation and optimization of hydrodynamic bearings.

Our bearing training courses offer you practical expert knowledge that you can apply directly in mechanical engineering or maintenance. You will learn how to design and calculate hydrodynamic bearings, understand the basics of tribology, lubrication and materials science. You receive practical solutions to typical bearing problems.The training courses help you to avoid errors, increase operational safety and improve your efficiency. They are ideal for engineers, designers, technicians and maintenance personnel who want to deepen their specialist knowledge and analyze specific applications from their everyday work.

Secure your place in our bearing training courses and benefit from practical expert knowledge.

Introduction to Miba Bearing Division

Fundamentals of hydrodynamic bearings

Types of hydrodynamic bearings

Principles of hydrodynamic bearings

Design of hydrodynamic bearings

p-v diagram

Bearing materials

Application fields of hydrodynamic bearings

Advantages of hydrodynamic bearings in this applications

Differences to other bearing solutions

Customer specific topics

Option A: Online training course: 4 hours

Option B: Training at the Miba site in Osterode (Germany) or Laakirchen (Austria), including a tour of the plant: 6 hours

Option C: Training at the customer's site: 6 hours

Introduction to Miba Bearing Division

Bearing design principles

Bearing validation process

Bearing damage and measures

Option A: Training at the Miba site in Osterode (Germany) or Laakirchen (Austria), including a tour of the plant: 6 hours

Option B: Training at the customer's site: 6 hours

Introduction to Miba Bearing Division

Bearing design principles

Optimization of hydrodynamic bearings

Bearing damage and measures

Option A: Training at the Miba site in Osterode (Germany) or Laakirchen (Austria), including a tour of the plant: 6 hours

Option B: Training at the customer's site: 6 hours

For those who are new to hydrodynamic bearings, we recommend starting with Module A.

We are happy to tailor our training courses to your needs. Contact us for a customized training offer!