- Company

- Industries

- Product areas

- Technology

- Jobs and Career

- Apprenticeship

- News

Discharge resistors ensure that DC link capacitors are discharged reliably and in a controlled manner after an electric vehicle is switched off.

✓ Automotive-compliant & AEC-Q200 tested

✓ High dielectric strength

✓ Compact, lightweight & non-inductive designs

Discharge resistors perform a key safety function in the high-voltage systems of electric vehicles and support safe operation as well as service and rescue operations.

Our modern discharge resistors are not only designed with safety in mind:

Arrange a non-binding consultation appointment now.

The following discharge resistors are designed for the safe discharge of DC link capacitors in inverters and high-voltage systems of electric vehicles. They meet the requirements of modern e-mobility applications in terms of safety, installation space, weight, and automotive series production capability.

All our discharge resistors have an operating voltage of up to 1,000 V and an ohm range between 0.1 Ω and 1 MΩ.

You can also view the individual discharge resistors in the product catalog.

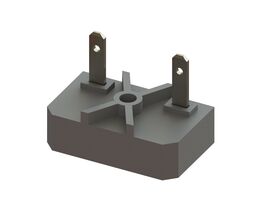

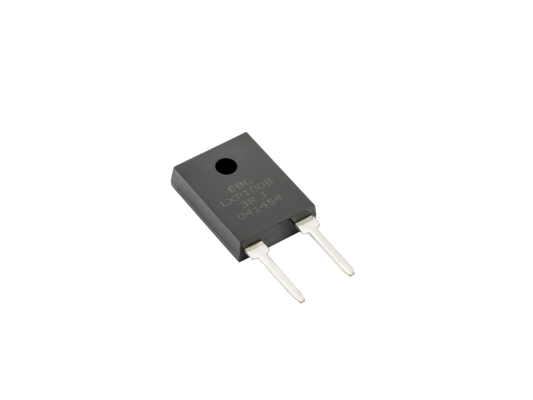

Very compact and lightweight discharge resistor for space-critical inverter designs:

→ Suitable for compact inverters and high-voltage systems with limited installation space and a focus on low weight

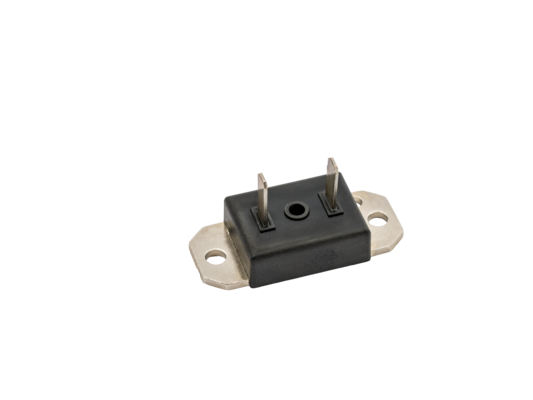

More powerful discharge resistor with optimized heat dissipation for more demanding inverter applications:

Continuous power 150 W at 85 °C

Baseplate for robust and efficient connection to the heat sink

Various connection options available (e.g., FAST-ON, cable, press-fit, solder pins)

Very good thermal performance with compact design

→ Suitable for inverters and high-voltage systems with higher discharge power and defined cooling concept

High-performance discharge resistor for applications with increased discharge energy and high thermal requirements:

→ Suitable for powerful inverters and high-voltage systems with high discharge energy and demanding thermal management

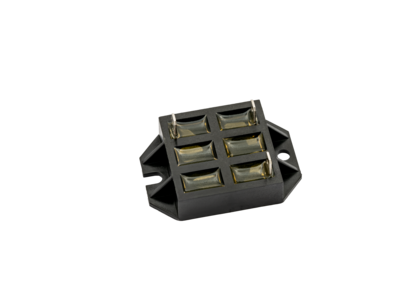

Highly powerful discharge resistor for high-voltage and high-power applications with increased system voltages:

Continuous power 800 W at 85 °C

Robust design for high electrical and thermal loads

Various connection types possible, including screw connections

→ Suitable for demanding industrial and automotive high-voltage applications

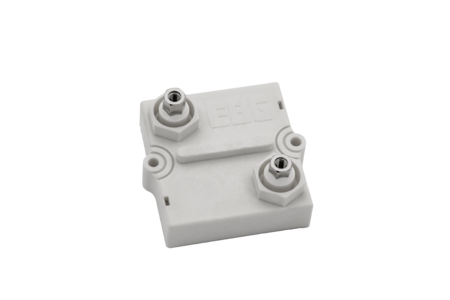

Highly compact discharge resistors for space-saving and lightweight inverter and circuit board designs:

→ Suitable for compact inverter designs with a focus on low weight and easy PCB integration

Download Data Sheet LXP 30 / 100 / 150

Universally applicable discharge resistors for applications with high continuous power and flexible integration requirements:

→ Suitable for powerful inverters and high-voltage systems with a defined cooling concept and increased discharge requirements

Highly compact, SMD-compatible discharge resistor for space-critical applications with high reliability:

→ Suitable for high-frequency and RF applications with a focus on SMD integration and minimal installation space

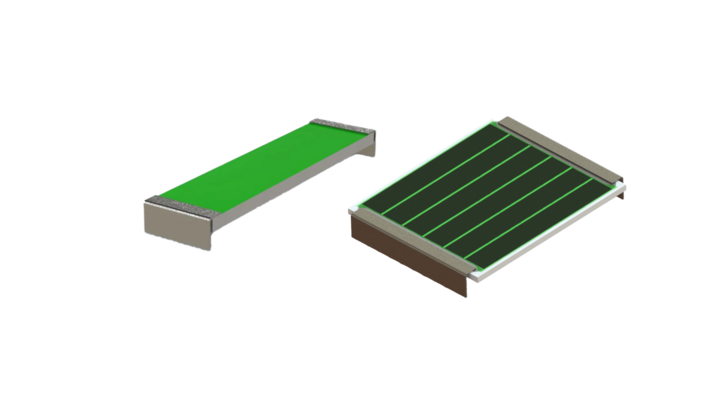

SMD-compatible discharge resistors for applications with high pulse energy and easy integration:

- EVR S300: 20 W

- EVR S1000: 15 W

- EVR S300: up to 300 J

- EVR S1000: up to 1,000 J

→ Suitable for discharge concepts with high pulse energy that require easy PCB integration without additional cooling measures

Specialized discharge resistor for safety-critical applications and crash scenarios:

→ Suitable for crash and emergency discharge in electric vehicles to reliably protect occupants, service personnel, and rescue workers

Contact us now!

Bleeding resistors are designed differently depending on the inverter architecture, system voltage, and discharge requirements. That is why custom engineering is an integral part of the development process.

This process follows a clearly structured sequence:

1. Definition of technical requirements

At the beginning, the relevant system parameters are defined jointly:

• System voltage and discharge time

• Ohm value, continuous power, and pulse energy

• Single pulse or constant power discharge

• Installation space, mounting position, and cooling concept

• Requirements for weight, integration, and service life

2. Electrical and mechanical design

The specific design of the discharge resistor is based on the requirements:

• Selection of the appropriate resistor series

• Adaptation of geometry and design

• Definition of connection technology (FAST-ON, cable, screw, press-fit, solder pins, or SMD)

• Design of the thermal connection via baseplate, heat sink, or printed circuit board

3. Integration of additional functions

If required, additional functions can be integrated into the component:

• Multiple discharge resistors in one module

• Active or passive discharge concepts

• Integration of a temperature sensor

• Adaptation to safety-related requirements

4. Validation in our in-house test laboratory

All customer-specific discharge resistors are tested in our own test laboratory:

• Electrical characteristics

• Pulse and continuous load behavior

• Thermal performance

• Insulation and dielectric strength

• Mechanical load capacity

This ensures that the discharge resistor reliably meets the requirements of the application.

5. Series production for automotive applications

After successful validation, series production begins:

• Automotive-compliant according to IATF 16949

• Scalable for small and large series

• Reproducible quality throughout the entire project period

Initial situation

A manufacturer of luxury electric sports cars was looking for a bleedinge resistor solution that could safely handle high discharge energy and be flexibly integrated into the existing inverter architecture.

Implementation

Together with Miba, a customer-specific discharge resistor was developed that is precisely tailored to the vehicle's high-voltage system. The solution was also extensively tested in the in-house test laboratory.

Result

The discharge resistor contributes to increased safety and reliability of the electrical system and meets the requirements of a high-performance electric vehicle platform.

Unloading resistors are manufactured in several international production plants, including:

This enables short delivery routes and regional support for OEMs and Tier 1 customers in Europe, North America, and Asia.

The discharge time is determined by the capacity of the DC link capacitor, the selected resistance value, and the safety-related requirements of the respective standard or vehicle architecture. The design ensures that the voltage is reduced to a safe level within the specified time.

A constant-power discharge is particularly advantageous when installation space and weight are critical or repeated discharge processes occur. It enables smaller and lighter discharge resistors with uniform thermal stress.

Yes, PCB- and SMD-compatible discharge resistors are available for many applications. Heat dissipation takes place via the printed circuit board, enabling compact integration into inverters and electronic modules.

Non-inductive bleeding resistors offer greater freedom in circuit design and prevent unwanted electrical effects. This is particularly advantageous in highly integrated power electronics.

Special fast discharge resistors are available for safety-critical applications. These are designed for very high pulse energies and ensure fast and reliable discharge of the high-voltage system in an emergency.

Yes, custom-designed discharge resistors are fully suitable for series production. After validation in our in-house test laboratory, production is carried out in accordance with automotive standards and is scalable for different quantities.

Depending on the product series and application, different connection types are possible, including

The selection is made on an application-specific basis.

All discharge resistors are tested in our own test laboratory and additionally monitored during series production. This ensures consistent quality throughout the entire duration of a vehicle project.

Miba produces precharging and bleeding resistors for charging and discharging the DC-Link capacitor for electric vehicles. They ensure safe and reliable operation for PRE and DIScharge applications. Our products are AEC-Q200 compliant.