- Company

- Industries

- Product areas

- Technology

- Jobs and Career

- Apprenticeship

- News

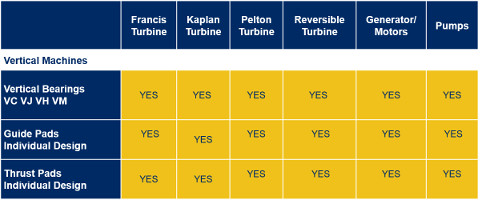

Miba Hydro Bearings are used in turbines and generators for small (below 30 megawatts), medium-sized (31 and 80 megawatts), and large (above 80 megawatts) hydropower plants. With 40 years of experience in hydro bearings, Miba is one of the leading manufacturers and reliable partners when it comes to engineering or repair. Our customers appreciate the wealth of expertise that our teams bring to the table.

Depending on the application (e.g. Francis, Kaplan, or Pelton Turbine), various products are available. We will be happy to advise you on which hydro bearing will enable the optimum performance of your turbine.

Depending on the application (e.g. Francis, Kaplan, or Pelton Turbine), various products are available. We will be happy to advise you on which hydro bearing will enable the optimum performance of your turbine.

Guide bearings for vertical and horizontal machines.

Combined bearings for bulb turbines.

Guide pads for vertical and horizontal machines.

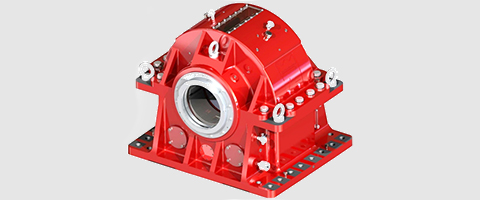

Pedestal bearing for hydro applications with higher thrust capability. Standard sizes up to ID 600 mm.

Customized sizes upon request.

Special design pads for vertical and horizontal machines.

Special designed combined bearings (thrust and journal) for waterpower turbines.

Miba is a specialist when it comes to service. Send us your old bearings for analysis and repair. We will keep you and your turbine up and running.

If you have problems or want to increase the bearing’s performance, we offer upgrades and redesign of the bearing to meet higher requirements.