- Company

- Industries

- Product areas

- Technology

- Jobs and Career

- Apprenticeship

- News

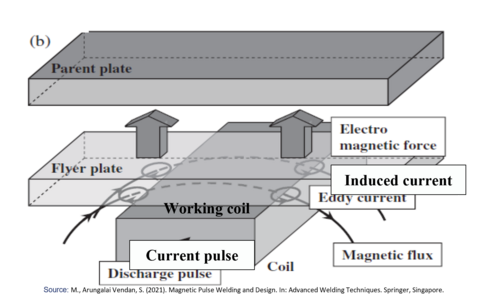

Electromagnetic pulse technology (EMPT) uses strong magnetic pulses to deform, join, or coat metals without contact or heat. It is particularly suitable for hydrodynamic bearings, as it creates robust multi-material bonds such as aluminum or copper on steel with high adhesive strength.

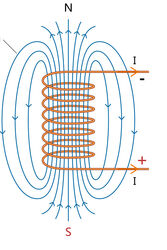

Electromagnetic pulse technology is based on an extremely short high-current pulse (100 kA–1 MA, <1 ms) that is conducted through a coil and generates a strong magnetic field. This induces eddy currents in the workpiece, causing repulsive Lorentz forces to deform the metal at the speed of sound or apply it to a carrier—completely contact-free and without heat. EMPT significantly improves manufacturing, especially for hydrodynamic bearings, as temperature-sensitive alloys such as aluminum or copper can be applied to steel carriers without structural changes.

Large capacitors store electricity like a battery, which is then conducted through a coil in milliseconds as an extremely powerful current surge (up to 1 million amps) – this generates a powerful magnetic field.

1. Charging: Charge the capacitor bank to kV level in 3–8 seconds

2. Pulse: High-current switch discharges 100 kA–1 MA in <1 ms through the tool coil

3. Magnetic field: Transient field (several tesla) arises locally at the workpiece

4. Induction: Opposing eddy currents in the conductive metal (aluminum/copper)

5. Acceleration: Lorentz forces propel the workpiece at 3x the speed of sound (<25 µs)

6. Contact: Plastic deformation or material bonding with a pressing force >1000 N/mm²

The entire cycle takes only a few seconds (5 to 10 seconds) and is scalable from prototype to series production.

Would you like to learn more about electromagnetic pulse technology?

Our technical team will be happy to answer your questions!

EMPT technology enables a wide range of precise manufacturing processes through highly dynamic, contactless material processing.

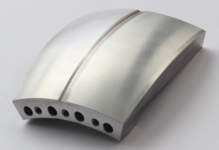

Ring, pipe, or plate connections, including multi-material (aluminum-steel), are joined cold and without additional material; strengths often reach 80-100% of the base material.

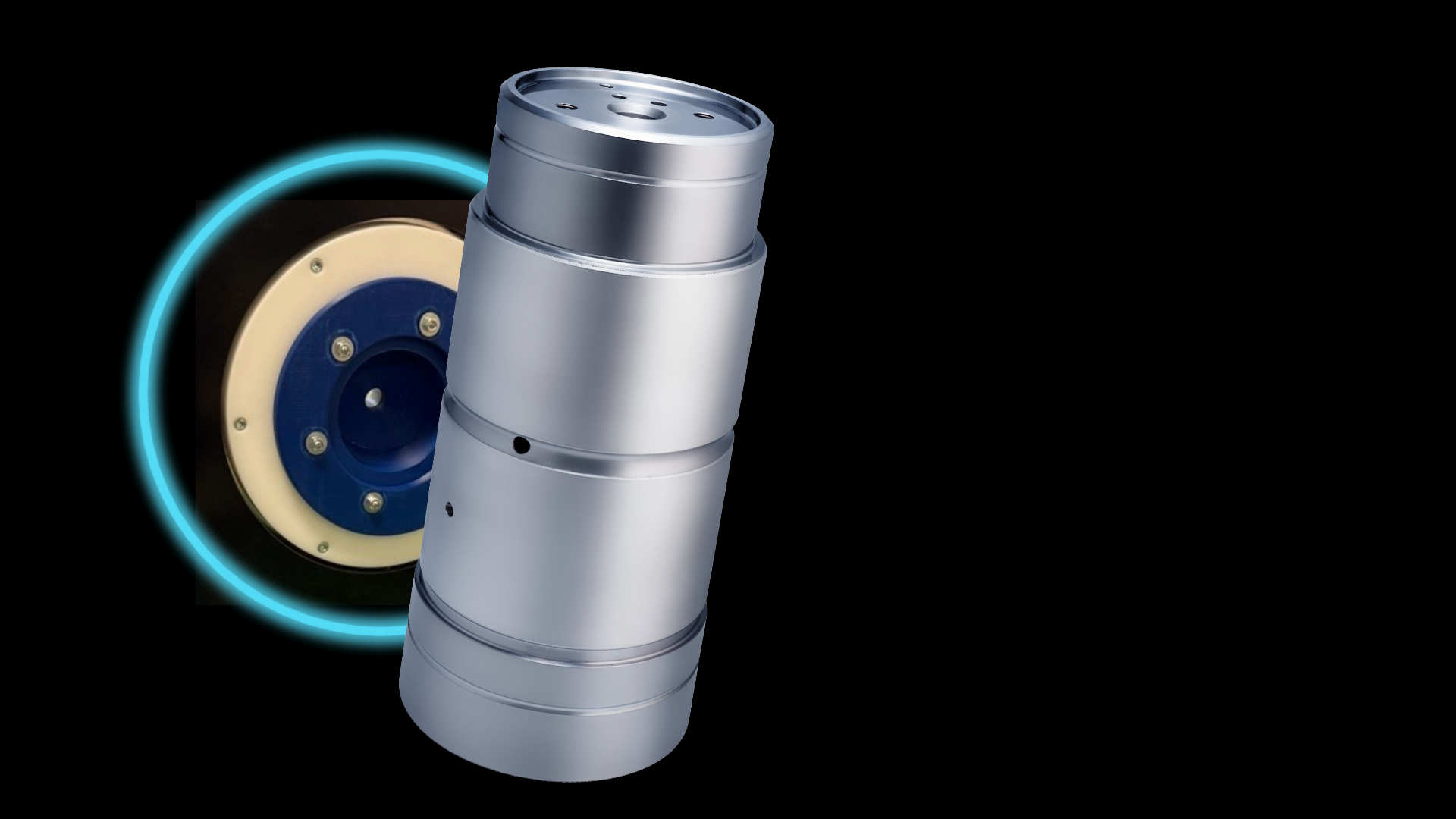

Precise joining of slide bushings: Sleeves or thin-walled slide bushings are compacted homogeneously onto bolt pins. This is ideal for press-fit connections in hydrodynamic bearings with >99.9% compression, backlash-free fit, and consistently low frictional resistance.

Tubes can be drawn in, expanded, drilled, or given complex contours—without tool marks or mechanical contact with the surface, which preserves surface quality and structure.

Localized field concentration separates pipes or profiles with minimal burrs through targeted plastic deformation, without wear tools or thermal zones.

Hydrodynamic bearings function by means of a self-forming lubricating film: This enables high specific loads (p >100 MPa), speeds (v >50 m/s), and extremely long service lives with minimal friction, but requires precise sliding layers with embedding capability and emergency running properties.

EMPT technology optimizes the production of these sliding layers. Bushings made of aluminum or copper alloys are applied to steel carrier bodies cold and without contact, thus avoiding structural changes, distortion, and heat influence. This is crucial for the tribological properties under high hydrodynamic loads.

No heat influence: Unlike laser cladding or sputtering, the structure of the substrate remains unchanged. There are no hardening or softening zones and only minimal risks of distortion.

Material-bonded multi-material joints: Aluminum adheres to steel with strengths close to the base material (80–100%), ductile and corrosion-resistant. Copper on steel with EMPT also achieves high strengths close to the base material (70–95%) in multi-material joints. Copper joints have better thermal conductivity for hydrodynamic bearings with high heat dissipation. These are often used for bearing bushings with integrated cooling structures or electrical contacts in bearings.

Wind energy gear bearings: Planetary bolts in bearings with aluminum/copper alloys to optimize sliding properties and heat dissipation under cyclic high loads

Engine plain bearings: Coating of connecting rod or camshaft bearing shells with temperature-sensitive alloys.

Industrial plain bearings: Heavy hydraulics, turbine bearings where emergency running properties and wear resistance are crucial.

With its electromagnetic pulse technology, Miba offers a highly integrated complete solution with a fully coated shaft—either as a standard Miba shaft or directly with customer-specific shaft blanks.

Compared to thermal press fits, there is no need for additional sleeves, adapters, or retaining elements, which enables significant space savings (typically 10–20 mm radial reduction) and reduces the overall weight. Large shaft diameters are possible without distortion, as the process remains local and heat-free—ideal for large engines and wind power transmissions.

EMPT performs well in direct comparison with other coating technologies in terms of material, component size, and system integration when thermal processes reach material or deformation limits.

| EMPT | Thermische Presssitze | Laserauftragschweißen | Sputtern/PVD | |

| Thermal effect | None (cold, <100°C HAZ) | High (ΔT 100–300°C, voltages) | Medium (HAZ 0.5–2 mm) | None (plasma <200°C) |

| Material combinations | Any (aluminum/copper on steel) | α-expansion pairing (steel/bronze) | Limited (aluminum, coated) | Limited (thin layer) |

| Installation space | Minimal (no sleeves) | +10–20 mm radial (sleeves/adapters) | Minimal | Minimal |

| Diameter | >500 mm without distortion | ≤300 mm (critical for warping) | ≤200 mm | <1 m² area |

| Delay | <0,05 mm | 0,1–0,5 mm | 0,1–0,3 mm | None |

| Adhesion | >50 MPa (80–100% basis) | Friction lock (2-5 MPa) | 30–60 MPa | 20–40 MPa (adhesion) |

Have you reached the limits of your press-fit or coating technology?

We will analyze free of charge whether EMPT can optimize your components. Contact us now!

Since Electromagnetic Plus Technology is relatively new and innovative, Miba offers a comprehensive testing and development platform that enables a safe transition. In close cooperation with leading universities, we have developed a validated simulation model that can predict adhesion, material penetration into the carrier structure, and long-term tribological properties even before actual production.

We seamlessly accompany our customers from the initial concept through prototype development to series production approval: Together, we optimize all EMPT parameters for your specific application – so that you can switch to this innovative technology safely and with low risk.

Would you like to know how EMPT works and whether the technology is suitable for your application?

Then talk to our experts. We will review your requirements together and find the right solution.