- Company

- Industries

- Product areas

- Innovation

- Jobs and Career

- Apprenticeship

- News

As a leading engine bearing manufacturer in the United States, Miba Bearings US LLC is dedicated to supporting customers who depend on reliable, high-performance applications - whether in locomotives, heavy-duty trucks, aviation spplications or industrial compressors.

As a manufacturer of hydrodynamic bearings, we also offer a comprehensive portfolio of bearings for the US market that are designed to meet the high demands of locomotives, trucks and compressors.

Bearings for locomotives: Our bearings are designed to withstand extreme loads and constant shock forces, ensuring reliable performance even under the toughest railway conditions. Lower friction and vibration increase efficiency and minimize maintenance downtime.

Bearings for compressors: Our solutions are optimized for high-speed and high-load compressor applications and offer excellent shock resistance, low noise, and long-term reliability.

Bearings in large engines ensure maximum load capacity, high efficiency and long service life. Their robust design enables them to withstand extreme forces and sudden load changes, such as those encountered in heavy trucks or construction machinery. Their compact design contributes to increasing the overall performance of the engine, while modern bearing technologies enable higher speeds and optimized thermal stability. The result: reliable performance, reduced downtime, and a significant

Bearings as spare parts: As a technology leader, our customers in the repair market also benefit from our innovative products. With well-planned warehousing and fast delivery processes, we ensure that the required products are available reliably and on time. In this way, we support our customers in implementing their projects efficiently.

In addition, our radial bearings are available with innovative material structures in the form of half-shells, bushings, or thrust rings for a wide range of applications.

As an experienced bearing manufacturer, Miba supports its customers throughout the entire product life cycle - from the initial idea to after-sales service. With this comprehensive approach, we ensure that every bearing solution is optimally tailored to your application and meets the highest requirements.

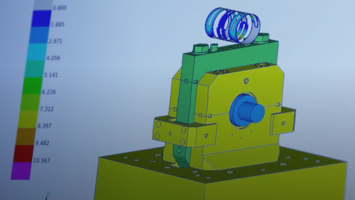

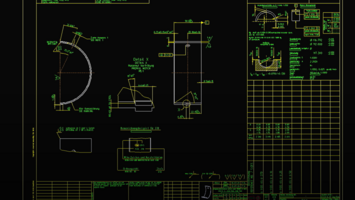

Thanks to our many years of experience as a bearing manufacturer, we support our customers right from the engine development phase. We actively support you in bearing design, bearing simulation and operational risk analysis. For this purpose, we provide test bearings, evaluate bearing performance in modern engine tests and can carry out extensive tests in our state-of-the-art laboratories and test benches. In this way, we ensure that your engines are designed for maximum reliability and efficiency right from the start.

Our experienced application engineers deal with the precise design of bearing geometries, material combinations and lubrication strategies for each specific application. A deep understanding of the complex interactions between materials, geometry and operating conditions is required to find the optimal design for each application. Together with our customers, our application engineers develop customized solutions for each application.

Miba has comprehensive material expertise for highly loaded bearing applications. We develop and process all relevant aluminum- and copper-based materials, each optimized for specific load profiles, thermal requirements and tribological properties. In addition, we rely on a wide range of modern surface technologies, including electroplated coatings, sputter coatings and the highly wear-resistant SYNTHEC® technology. This combination of material diversity and coating expertise enables us to tailor hydrodynamic bearings precisely to the needs of our customers.

Thanks to our own Advanced Bearing Materials (ABM) plant in Greensburg, Indiana, where we produce raw materials, we have a fully controlled and traceable value chain. This means that our customers can consistently rely on high-quality materials, stable mechanical and tribological properties and a high level of supply security. We can coordinate alloys, layer structures and material parameters internally. In addition, local pre-material production enables us to deliver more quickly and implement individual requirements rapidly.

.

Miba Bearings US, LLC

5037 North State Route 60,

McConnelsville, Ohio 43756

USA

Our processes and products comply with international quality standards:

![[Translate to English:] Produktbild Axiallager](/fileadmin/_processed_/e/3/csm_Axialgleitlager_1afab24aaf.png)

Miba's Industrial Bearings Division manufactures hydrodynamic bearings and labyrinth seals for use in critical rotating equipment such as turbines, compressors, generators, motors and industrial pumps. We manufacture products for the US market at three locations:

Miba Industrial Bearings US Grafton, Wisconsin

Miba Industrial Bearings US Columbus, Nebraska

Miba Industrial Bearings US Houston, Texas

Together, we will develop the right solution for your bearing application!