- Company

- Industries

- Product areas

- Innovation

- Jobs and Career

- Apprenticeship

- Kariéra

- News

As global contact for hydrodynamic bearing repair and refurbishment, Miba provides you with fast and straightforward support. Our comprehensive services includes bearing refurbishments an bearing overhaul, ensuring that your equipment is restored to optimal condition.

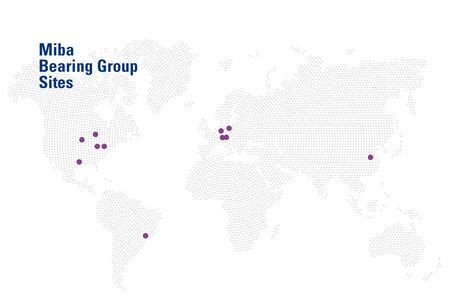

Our global service locations enable us to provide rapid assistance exactly where you need it.

Customized solutions, precisely tailored to your requirements. Whether you require a complete bearing overhaul or targeted bearing refurbishment, our team delivers solutions that meet your specific needs.

We ensure your productivity through rapid analysis and efficient processes in hydrodynamic bearing repair.

Our experts will accompany you from the initial contact to the successful recommissioning.

With specialized repair facilities in Europe, North America, and South America, Miba is there for you worldwide. Our international presence enables us to carry out hydrodynamic bearing repairs and maintenance quickly, reliably and close to your location. This minimizes downtime and enables smooth operation of your systems.

Close coordination with our customers results in customized repair and maintenance solutions that not only take effect quickly but also have a long-term impact.

Whether you are experiencing malfunctions, noticeable vibrations, or declining system performance, our team of experts is ready to help. Contact us for an initial assessment.

1. Disassembly & shipment

The hydrodynamic bearing can be sent directly to Miba. If the hydrodynamic bearing cannot be shipped, a series of informative digital images will suffice.

2. Analysis & diagnosis

Our experts check the condition of the hydrodynamic bearing, using informative images if necessary, and prepare a detailed analysis with a transparent cost estimate.

3. Professional repair & refurbishment

Depending on the case, individual components are machined, relined, coated or replaced – precisely and using state-of-the-art technology.

4. Quality assurance

All hydrodynamic bearings undergo comprehensive testing to the highest standards, including precise measurements and detailed test reports.

5. Return delivery & support

After refurbishment or repair, we ensure safe and on-time return delivery. On request, we can also supervise assembly and recommissioning on site.

Competitive pressure, rising customer expectations, high operating costs, and scarce human resources present companies with major challenges every day. At the same time, environmental and safety standards are becoming increasingly stringent. In this challenging environment, the smooth operation of your machines is crucial—unplanned downtime puts a strain on resources and budgets.

We know these requirements from practical experience: Fast response is crucial – that's why we minimize downtime, take a holistic approach to every hydrodynamic bearing repair and maintenance, and tailor our solutions precisely to your requirements.

Whether simple repairs or complex overhauls – we support you with technical expertise, reliability, and a service that really takes the strain off you.

“When a gas turbine suffered acute bearing damage, we were able to help an energy supplier within a few days – from removal and repair to delivery ready for installation. In situations like this, every hour counts.”

Sascha Macke

Service expert at Miba

We focus on long-term solutions. That's why we not only repair hydrodynamic bearings quickly and reliably, but also analyze every problem in detail and go one step further. Our approach encompasses both bearing refurbishment and bearing overhaul, aiming to enhance performance and extend service life.

More about the development of hydrodynamic bearings Our hydrodynamic bearing services

Miba is one of the world's leading manufacturers of hydrodynamic bearings. With fast hydrodynamic bearing repair and maintenance efficient processing, and interdisciplinary teams with decades of experience, we are your reliable partner—worldwide and exactly when you need us.

Typical damage to hydrodynamic bearings is caused by high temperatures, uneven loads or inadequate design – and can lead to premature wear, unplanned maintenance and even the failure of entire machines.

Miba meets these challenges with detailed damage analysis, customized hydrodynamic bearing repair and targeted optimization. Our experts develop individual solutions that not only repair the damage but also improve bearing performance in the long term – for example, through innovations for temperature reduction or extended maintenance intervals without costly machine modifications.

Miba repairs a wide range of hydrodynamic bearings, including axial bearings, radial bearings, and bearing pads for a variety of industrial applications, e.g., in the oil and gas, steel, power generation, mining, and chemical industries.

These include bearings in steam and gas turbines, hydroelectric turbines, electric motors, expanders, pumps, gearboxes, mills, generators, gear compressors, and centrifugal compressors.

Even complex sealing systems such as labyrinth seals can be repaired or optimized for specific applications.

We analyze and repair hydrodynamic bearings of various sizes, geometries, and material combinations, including:

Our goal: A technically and economically optimal solution – precisely tailored to your requirements. Contact us to discuss the refurbishment or repair options for your specific hydrodynamic bearing.

Whether repair is possible and economically viable depends on the condition of the bearing and the specific requirements. Our specialists first carry out a comprehensive analysis and assess whether repair is technically feasible and advisable in the long term.

Based on this, we work with you to develop the best possible solution – whether that's repair, optimization, or, if necessary, a new part. The goal is always the same: maximum operational reliability at minimum cost.