- Company

- Industries

- Product areas

- Innovation

- Jobs and Career

- Apprenticeship

- Kariéra

- News

With the Miba FLEXcooler®, Miba offers a liquid cooling system for EV batteries that is suitable for the thermal management of all cell types, sizes and shapes.

We'll be happy to explain the Miba FLEXcooler® to you.

Our flexible battery cooling is compatible with every cell type on the market, whether pouch, prismatic or cylindrical cells of all formats.

The same applies to the cooling direction. The Miba FLEXcooler® can be integrated to cool the bottom, pole, tab or side of any type of battery cell. Once the FLEXcooler® has been integrated in the selected cooling direction, it inflates due to the coolant flow in its flow field until a positive connection is made between all surfaces to be cooled, without the need for TIM or other filling agents.

We would be happy to answer open questions in a non-binding consultation appointment.

Contact us now!

Thermal management is a critical success factor for electric vehicles. Long service life, short charging time and energy density are directly related to an efficient battery cooling system.

Traditional battery cooling takes the form of a plate, usually made of aluminum, with embedded channels for the coolant. The battery cells, which are usually surrounded by a metal sleeve, and the cooling plate are rigid. Direct contact - e.g. due to manufacturing tolerances - always results in an air gap and thus poor thermal conductivity. By adding thermal conductive pastes, good thermal coupling can be achieved at this point.

Miba's flexible battery cooling system now replaces the cooling plate with a heat exchanger that adapts to the shape of the battery cell. The flexibility of the heat exchanger enables direct thermal contact between the heat exchanger and the battery cell, even without the use of a heat-conducting paste.

Then contact us now.

We offer a closed-loop approach from initial concept studies, through development to industrialization and large-scale production of the most efficient, lightweight and sustainable cooling components available on the market.

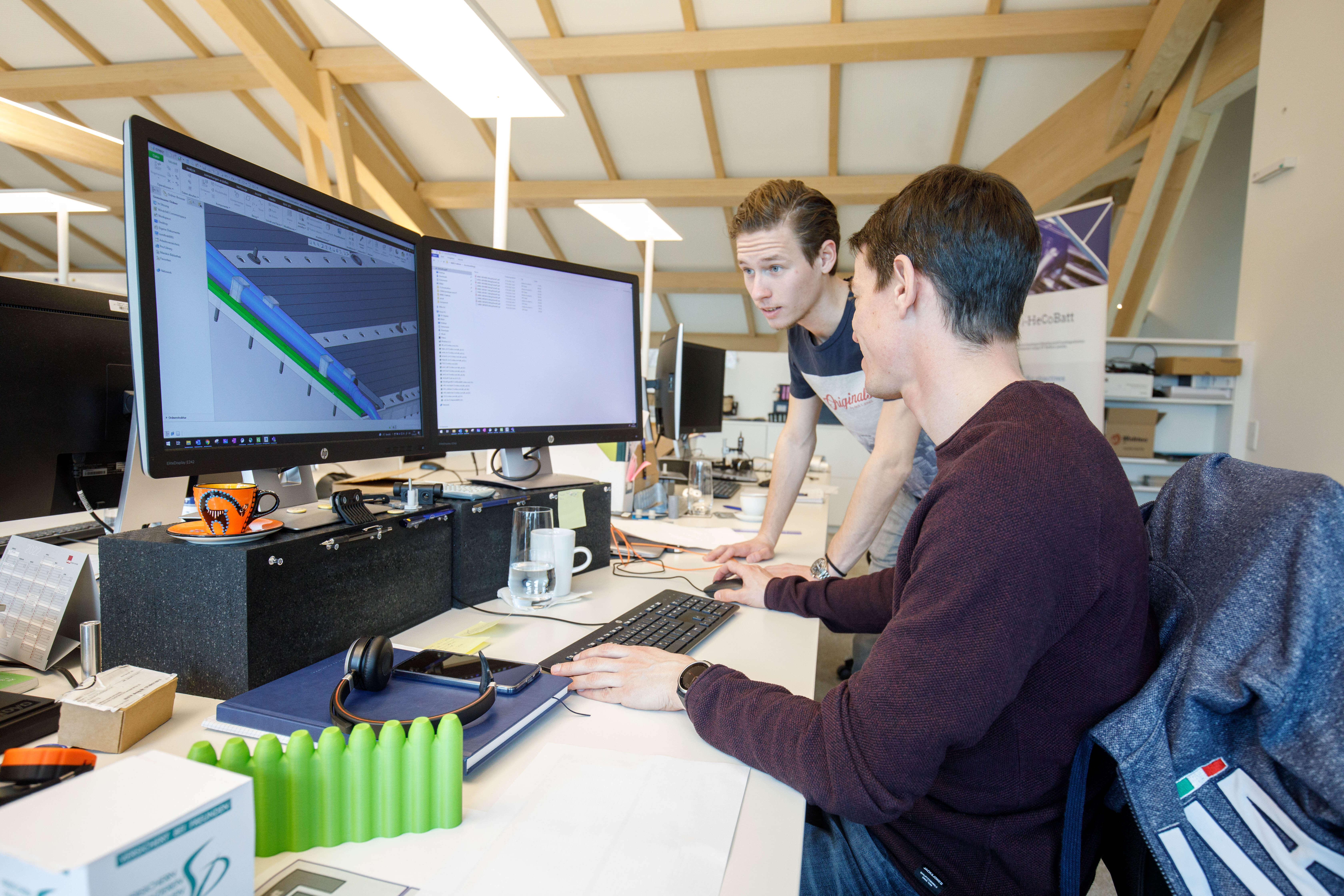

Our research and development team provides support for the design and validation of flexible battery cooling systems. We have in-house state-of-the-art test rigs to perform functional tests such as life cycle, aging, performance or abuse tests.

Miba Battery Systems develops and produces lithium-ion battery packs and energy storage systems based on laser-welded cylindrical cells. By combining them with the Miba FLEXcooler®, we significantly reduce the weight and cost as well as the CO2 footprint of the battery. The knowledge gained from battery production also flows into the continuous further development of battery cooling solutions.

Our battery specialists support you globally. With a Miba network of 30 locations in America, Europe and Asia, we are available to our customers at all times.

Our flexible battery cooling adapts perfectly to the battery cell housing, even if the hydrostatic pressure of the cooling circuit is only 0.05 bar. This results in efficient thermal coupling. Since a gap filler is no longer needed, weight is saved and a fixed connection between the heat exchanger and the battery modules is also avoided. This makes it realistic for the first time to easily separate battery and heat exchanger for recycling and repair purposes.

- Franz Pöhn -

Team Lead Development Battery Components